Description

High Volume Low Speed Industrial HVLS Fans Technical Parameters

| Model | Fan diameter (m)ft | Motor power (kw) | Rotate speed (rpm) | Full load current | Air volume (CMM)m3/min | Weight (kg) | Max coverage (m2) | Noise (dBA) |

|---|---|---|---|---|---|---|---|---|

| BGX-TD-7E | 7.3(24′) | 1.5/2.0 | 0-53 | 2.95 | 13800 | 125 | 1800 | 43 |

| BGX-TD-6E | 6.4(21′) | 1.5/2.0 | 0-53 | 2.72 | 12800 | 113 | 1400 | 43 |

| BGX-TD-5E | 5.5(18′) | 1.5/2.0 | 0-65 | 2.75 | 12000 | 108 | 1050 | 43 |

| BGX-TD-4E | 4.6(15′) | 1.5/2.0 | 0-65 | 2.85 | 11500 | 102 | 850 | 43 |

| BGX-TD-3E | 3.7(12’) | 1.5/2.0 | 0-70 | 2.72 | 10500 | 90 | 680 | 43 |

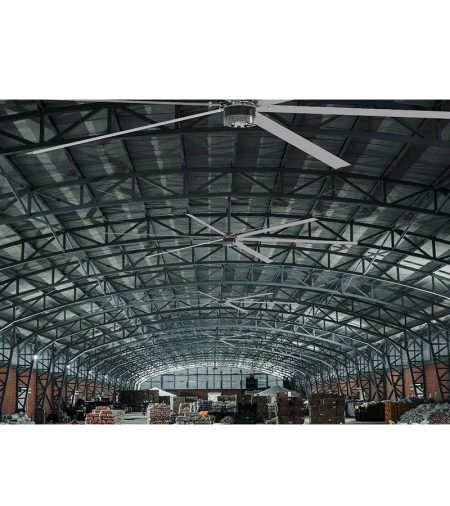

FEATURES OF TRADITIONAL HVLS FANS

Motor Reducer

German imported ABM motor, 42CrMo output shaft & double tapered bearing; low pressure cast aluminum (special gear arrangement); Dust-proof oil seal (double oil seal design); No breather cap, maintenance-free; Ultra low energy consumption; Super fine grinding.

Control System

Our big industrial fan used Denmark ‘Danfoss’ transducer, the built-in RF interference filter and the brake chopper have the function of restraining radio interference and braking;

It has the functions of earth fault, over and short circuit protection, and so on;

The box is equipped with Schneider three gear switch and infinitely variable speed knob.

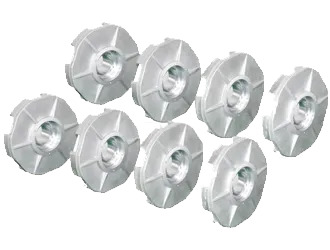

Hub

Import American Airlines AA7075 super hard alloy + Japanese precision high pressure forging technology (sigma B 600Mpa) +T6 heat treatment +CNC precision machining + dynamic balance check quality;

Industrial HVLS fan hub is built by Japanese senior corporation, which focuses on precision forging of aluminum alloy for 60 years. The product quality is absolutely guaranteed. Ensure the product’s tolerance and dynamic balance are as accurate and reliable as the hub of a car. Hub and motor cover are put together.

Jiangsu Gaxiao Environmental Technology is the prior company in China adopting the combination device of anti falling disk and hub top cover, that is to ensure we are the outstanding factory who combines upper, lower chassis with fixed fan wing to solve the safety problem (at present, the other manufacturers mostly use the single chassis so as to reduce cost). At the same time, this reduces the weight of the whole big industrial ceiling fan , and improves the efficiency of the motor to realize perfect combination.

The anti falling disk adopts the lower part closely connecting with hub. This improves the current market situation of connecting anti falling disk with frame, which exists a certain risk of operating.

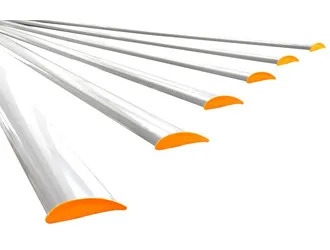

Fan Blade

The size of the industrial ceiling fan blade is amplified by 20% of all the current fan sizes, which will increase the air volume. It also proves that the weight of the whole machine is reduced and the efficiency of the motor is improved.

The fan blade adopts the internal steel cable, the stiffened reinforcement combination, the fan blade and the fixed point line and surface safety method. (at present, two bolts are used in the fixed way in China, and it is easier to aggravate the damage of the fan blade fatigue point).

6 propeller shape, import American Airlines high performance aluminum alloy material:

AA6063T6511

-Long-life warranty;

Shape design developed by Profili V2 airfoil simulation analysis software

-To ensure the maximum comfort of the fan effect